Xona Rotor XRE 6869S X4C Turbocharger: Unleash 1050hp with 107lb/min Flow for Ultimate Performance and Reliability

Max Compressor Flow: 107lb/min | Power Applications: 700-1050hp

XRE 6869S X4C Specs

- Power Applications: 700-1050hp

- Compressor Wheel: 68/88.4mm

- Mass Flow: 107lb/min

- Turbine Wheel: 78/69mm

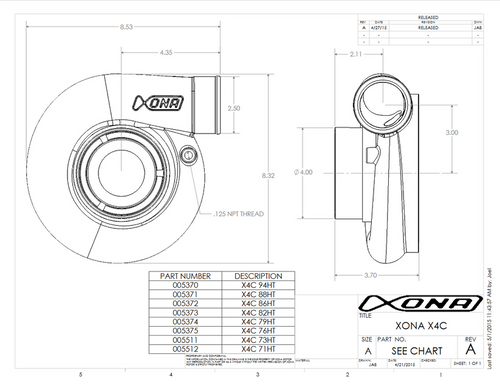

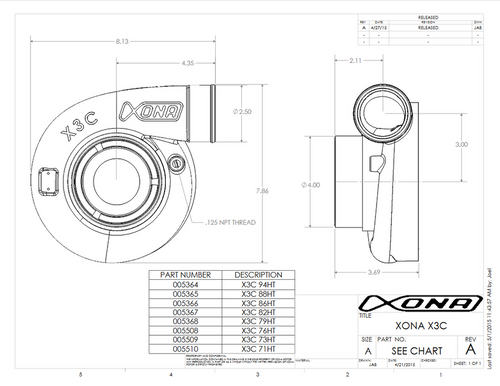

- Compressor Housing: X4C

Turbine Housing Options

All of these turbine housings are a proprietary austenitic stainless steel with high nickel content. Investment cast to minimize weight yet can cope with temperatures up to 1,900 degrees F.

| Turbine Housing Model | Part Number |

| .63 A/R TiAL V-Band In/Out | PN: 006878 |

| .82 A/R TiAL V-Band In/Out | PN: 006879 |

| 1.03 A/R TiAL V-Band In/Out | PN: 006880 |

| T3 .63 A/R V-Band Out | PN: 006911 |

| T3 .82 A/R V-Band Out | PN: 006912 |

| T3 1.06 A/R V-Band Out | PN: 006913 |

| T3 1.21 A/R V-Band Out | PN: 007188 |

Additional Info

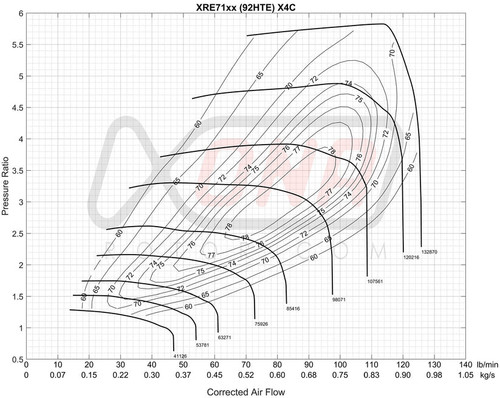

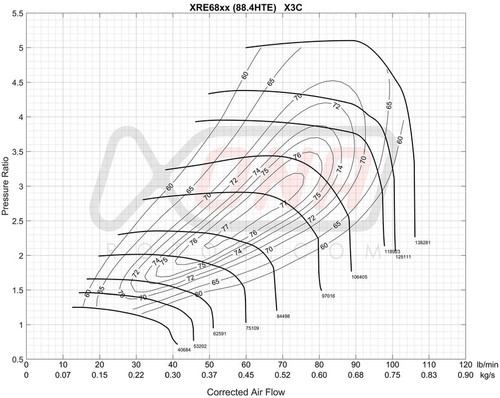

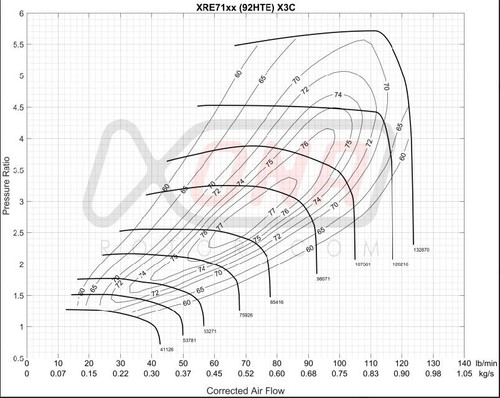

Compressor Map

View the compressor map for the XRE 6869S X4C, generated using the industry-leading CFD package ANSYS CFX and validated with experimental data and testing.

Next-Generation UHF Turbine

Xona Rotor's all-new, proprietary UHF (ultra high flow) turbine wheel is resetting the bar for turbocharger performance. Discover more about UHF turbine technology. UHF's splitter-blade design allows it to flow like a larger-diameter wheel without the associated inertia penalty. The result is superior boost response and less power-robbing backpressure.

Dual-Row Ball Bearing Cartridge

With silicon nitride ceramic balls, M62 tool steel races, and metallic cages, Xona Rotor's dual-row ball bearing cartridge ensures robustness to the most extreme operating conditions. Read about Xona's advanced bearing systems, engineered in cooperation with one of Germany's most prestigious manufacturers of high-precision rolling-element bearings.

CNC-Machined Billet Stainless Steel Center Housing

The workhorse of every Xona Rotor turbocharger is a fully-machined high-strength 17-4PH stainless steel center housing with a true 360-degree water jacket. By fully surrounding the turbine seal ring area with coolant, this center housing enhances durability by preventing piston ring collapse at high temperatures.

Dual Piston Rings

Most Performance turbochargers today use a single piston ring for sealing the shaft at each end. By contrast, Xona Rotor turbochargers employ twin rings at both the compressor and turbine ends, dramatically reducing oil leakage and gas intrusion. Spreading the sealing load across two rings also slashes wear rates and seal life.

Integrated Oil Filter and Modular Oil Drain

Built into the oil inlet cavity of a Xona Rotor center housing is a large-volume "last ditch" oil filter element. This feature protects the bearing system from oil contaminants, ensuring long bearing life. On the oil discharge side of the center housing is a modular oil drain surface with provision for a variety of bolt spacing configurations.

Modular Compressor Housing

Several compressor housings with different inlet and outlet dimensions allow packaging flexibility to suit the most demanding installations. Check out Xona's range of compressor housings and frame sizes.